For Any Queries Call Us at +91 91360 26188

Magna 940

Magna Electrodes

Trust Magna 940 – Ease of Application – Wide Versatility – Outstanding Physical Properties

- Patches and seals virtually any material.

- Repairs in 15 minutes – hardens in an hour.

- Easy to use – requires no special tools or training.

- Works on wet surfaces – even under water!

SPECIAL FEATURES

Magna 940 “Rapid Repair” Compound is the breakthrough “helper” for hundreds of minor repairs for metal and other materials.

• Magna 940 forms a reliable and durable patch or seal in as little as 15 minutes and fully hardens in less than an hour.

• Magna 940 is easy to use – requires no special tools or training.

• Magna 940 quickly adheres to almost any surface, even under water.

OUTSTANDING PROPERTIES

Magna 940 is the super rapid repair compound that:

• Features an advanced rosin compound with special fillers, including bronze powder.

• Can be machined, drilled, filed or tapped when fully cured.

• Is non-magnetic for use around gauges and other sensitive metering devices.

• Is formulated to be chemically resistant and extremely corrosion resistant.

USE FOR

Magna 940 “Rapid Repair” is the compound you apply in three easy steps:

1. Cut off exactly the amount required – no waste.

2. Knead product to mix the co-reactors.

3. Apply onto surface to be repaired.

Use Magna 940 “Rapid Repair” for

• Virtually All Metals • PVC • Glass • Wood • Concrete • Ceramic • Brick • Tile • Porcelain • Plastic Surfaces

Magna 940 is a totally new type of Instant Repair Compound that provides every workshop with the means to make speedy and sound repairs on surfaces and parts made of steel, copper, aluminium, cast iron, stainless, galvanized, brass and chrome. It features many advantages over conventional weld repair methods, especially where heat input using gas rod or electrode would require extensive dismantling, heat screening, re-assembly or even difficult access – such as in on-site work, or at height or using scaffolds. No special tools or training are required to successfully apply Magna 940 and, where required, It can be machined, drilled, filed or tapped after fully curing. Repairs can be completed in as little as 15 minutes and full cure is obtained in about 1 hour. Magna 940 is an advanced resin compound with special fillers engineered into it, including bronze powder, to give the product these special features:

∙ Will not rust or oxidize

∙ Product is non-magnetic and can be used in and around gauges and other sensitive metering devices or apparatus.

∙ It is chemical resistant and extremely corrosion resistant.

∙ The product works fast – -and yet can be re-shaped for a full 5 minutes after applying as initial curing takes place in 15 minutes and full cure is attained in 1 hour.

∙ Magna 940 will adhere even to damp or wet surfaces and will even cure while immersed completely in water or other non-reactive liquid media.

∙ There is no waste as the operator can use only the exact the amount required without contamination problems with the left over portions of the product.

∙ Magna 940 has an indefinite shelf life when stored properly and its handle, carry-anywhere size makes it perfect for virtually any type of on-job repairseven in remote sites.

∙ This product can be used as a sealant, adhesive, putty or cement and can be used on non-ferrous applications such as, PVC, glass, wood, concrete, ceramic, brick, tile, porcelain and plastic surfaces and parts equally as effectively as when used on metals.

PRECAUTIONS

Magna 940 can be used for a multitude of maintenance and repair applications. It may cause irritation to sensitive skin and surgical gloves are recommended for most situations. Wash hands with soap and water after using product. In case of eye contact, flush with copious amounts of water and contact physician. May be harmful if swallowed. Magna 940 was engineered for professional or industrial applications and should be kept out of reach of children.

SPECIFICATIONS

• TENSILE STRENGTH: 8,200 p.s.i. (5.77kg/mm2)

• COMPRESSIVE STRENGTH: 19,000 p.s.i. (13.36kg/mm2)

• SHEAR STRENGTH: 950p.s.i. (0.67 kg/mm2)

• SHORE “D” HARDNESS: 90

• MAX. OPERATING TEMPERATURE: 550oF(288oC)-INTERMITTENT 500oF(260Oc) – CONTINUOUS

• WORKING TIME: 5 minutes (before initial cure)

• CURING TIME: 60 minutes (@20Oc, RH50%)

• MODULES OF ELASTICITY: 6 X 105 p.s.i.

• VOLUME RESISTIVITY: 5 X 1015 Ohm-cm

• DIELECTRIC STRENGTH: 400 volts/mil@0.125 power m

• SHELF LIFE 2 YEARS

APPLICATION:

Applying Magna 940 is simple and foolproof and no tools or special equipment is necessary.

1. Uncap the tube holder.

2. Unwrap from plastic protector and peel off the foil paper at one end.

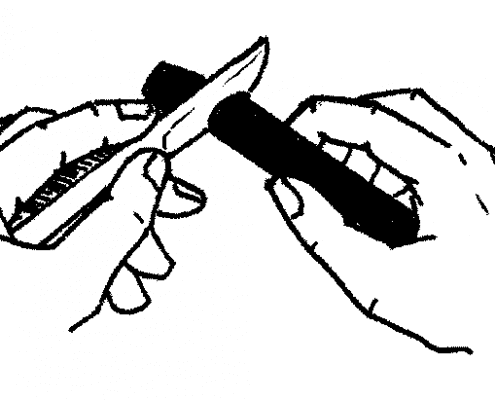

3. Use a knife or a pair of scissors and cut off a portion of Magna 940 sufficient for the repair you wish to apply it to. Replace foil paper, rewrap in plastic and return to tube holder.

4. Mix the it by kneading the portion thoroughly using your fingers or by rubbing it with your palms on a flat clean surface. 5. It will give off a slight amount of heat when kneading. This a natural and nothing to be alarmed about.

6. Work it into the part(s) to be repaired or sealed. Press the product firmly into the piece to be repaired to ensure it fully covers the area and to enable it to work into any recesses present.

7. Re-shape the Magna 940 rapidly to the desired shape (within 2 to 5 minutes of initial mixing).

8. Should a smooth surface finish be desired, hand rub the Magna 940 with some water or use a damp spatula to smooth out any rough edges or ribs. (You must do this within 5 minutes of initial mixing.)

9. Magna 940 attains full cure in 60 minutes and can them be machined, filed, tapped, drilled, etc.