For Any Queries Call Us at +91 91360 26188

Jetline – Automated Seam Welding Machine

Welding Products > Jetline

Automated seam welding machine manufacturer – Jetline, is the brand that offers flexible solutions, maximizing productivity for high-integrity welds.

Redefining Welding Excellence Across India

The Jetline difference

As Miller® products, Jetline® automated seam welding machine systems consistently enable high-integrity welds with the best return on investment. Here’s what makes Jetline systems valuable to your business:

> Turnkey systems. Complete solutions that are quicker to set up and easier to integrate — from a single-source supplier.

> Retrofit solutions. Cost-effective solutions that extend the useful life of existing equipment.

> Robust, reliable designs. High-precision travel and positioning results in consistent weld accuracy, reducing risk.

> Proven bolt-on controllers and accessories. These standard options are flexible and adaptable to your business’s needs.

We exclusively represent Jetline products all across India.

Jetline® Arc Length Control

Jetline Arc Length Control maintains a constant preset arc length by controlling arc length via control of the arc voltage in several processes such as TIG/ Plasma (PWA)/ SAW welding applications.

Jetline® Cold Wire Feeder

Jetline cold wire feeder is primarily used for Automated gas tungsten arc welding (TIG) and plasma arc welding (PAW) to add “fill” to a weld joint. They can also be used in other applications where a controlled feed of wire is required.

Jetline® Tactile Seam Tracking Systems

Jetline® Tactile Seam Tracking Systems simplify welding operation, be ensuring the weld head is consistently positioned for optimal arc performance

Jetline® Hot Wire Feeder

The hot wire process is used in applications where a high deposition of the filler wire is desired. It is used primarily with the GTAW (TIG) or the PAW (Plasma) welding process. The HWP-50F is capable of controlling both hot and cold wire feed.

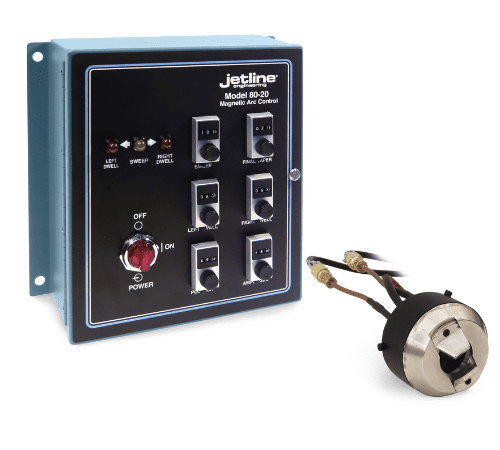

Cyclomatic® Magnetic Oscillator

Cyclomatic® Magnetic arc controls can provide even heat distribution, prevent undercutting, eliminates excessive porosity, ensures sufficient penetration, and evens out the weld puddle for TIG (GTAW) and Plasma Arc Welding (PAW).

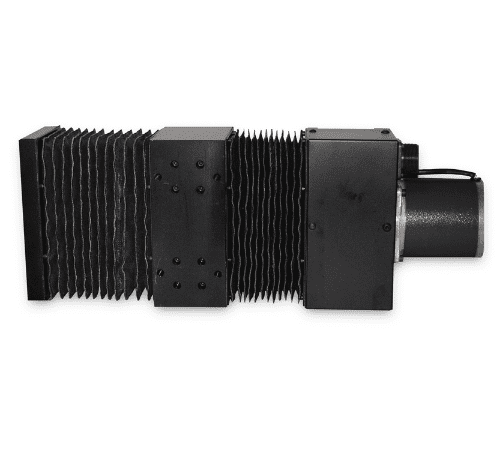

Jetline® Mechanical Oscillators

Oscillating the arc can help with sidewall fusion, eliminates undercut, and is required when preforming most overlay and cladding operations.